Specification:includes left and right wheels (1 pr.), width 12.7±0.1mm diameter 51.7mm

Sand paper:12.7mm x 160mm 180 / 360

USA Taber

Selecting Abrading Wheels

The choice of abrading wheels for Taber Rotary Platform Abraser should be based upon the wear the specimen material will be subjected to in actual use.

Abrading wheels for Taber Abrasers include five general types of varying abrasive quality:

• Calibrase® - a resilient wheel composed of resilient binder and aluminum oxide or silicon carbide abrasive particles

• Calibrade® - a non-resilient wheel composed of vitrified (clay) and silicon carbide or aluminum oxide abrasive particles

• Wool Felt - no abrasive particles

• Plain Rubber - no abrasive particles unless used with sandpaper strips

• Tungsten Carbide - extremely severe cutting and tearing action with helical teeth for use on resilient materials such as rubber, leather or floor covering.

The plain neoprene rubber wheel containing no abrasive grain is used for testing dental cleaning powders, dentifrice and for mounting sandpaper strips which are used as resilient wheels. These sandpaper strips must be changed after each 500 cycles of operation. The wool felt wheel is valuable in testing the wearing qualities of two fabrics in friction with one another.

NOTE: Calibrase Wheels must be used before the expiration date printed on the wheel.

|

H-10 - #125323

Calibrade abrasive wheels - non-resilient; gray; fine abrasive; includes left and right wheels (1 pr.). Used to evaluate materials such as steel and other ferrous alloys. |

|

H-18 - #125324

Calibrade abrasive wheels - non-resilient; gray; medium abrasive; includes left and right wheels (1 pr.). Recommended for testing leather, rubber, woven textile fabrics, coated fabrics, flexible plastic sheet, and other soft resilient materials. |

|

H-22 - #125325

Calibrade abrasive wheels - non-resilient; gray; coarse abrasive; includes left and right wheels (1 pr.). Used to evaluate rubber, linoleum, leather, deep pile fabrics, and concrete. |

|

H-38 - #125326

Calibrade abrasive wheels - non-resilient; tan; very fine abrasive; includes left and right wheels (1 pr.). Principle use is for woven fabrics or delicate textiles. |

|

CS-10 - #125320

Calibrase abrasive wheels - resilient; green; mild to medium abrading action; includes left and right wheels (1 pr.). Popular wheel used to evaluate resistance of wear on materials such as coatings, textiles, and leather products.

|

|

CS-10F - #125321

Calibrase abrasive wheels - resilient; brown; mild abrading action; includes left and right wheels (1 pr.). Used to evaluate resistance of transparent materials to haze (reface with ST-11 Refacing Stone, use oversize vacuum pickup).

|

|

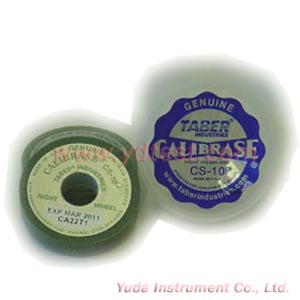

CS-10P - #132684

Calibrase abrasive wheel set for - resilient; green; mild to medium abrading action; includes left and right wheels (1 pr.). Specifically designed to evaluate fibrous materials such as paper and paperboard. Similar to CS-10 but wheel faces do not load.

|

|

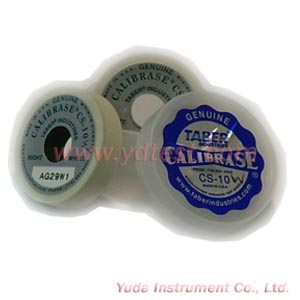

CS-10W - #130950

Calibrase abrasive wheels - resilient; white; mild to medium abrading action; includes left and right wheels (1 pr.). Same as CS-10, but no colorant added.

|

|

CS-17 - #125322

Calibrase abrasive wheels - resilient; green; medium - coarse abrading action; includes left and right wheels (1 pr.). Used to test anodized aluminum, ceramics, plastics, and enamels.

|

|

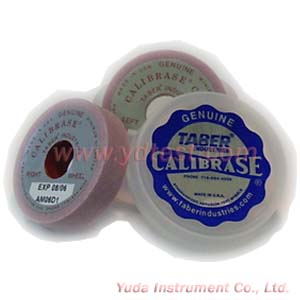

CS-T3 - #132661

Calibrase abrasive wheels - resilient; red; mild abrading action; includes left and right wheels (1 pr.). NOTE: Previously sold as CS-10F (type III), recommended to reface with ST-11 Refacing Stone.

|

|

CS-5 - #125319

Felt wheel set - resilient; densely compacted wool felt; white [no abrasive]; includes left and right wheels (1 pr.). Principal use is in testing textile fabrics to evaluate one fibrous material rubbing against another.

|

|

CS-0 - #125344

Calibrase wheel set - resilient; black rubber [no abrasive]; includes left and right wheels (1 pr.). Mount S-33 or S-42 sandpaper strips to periphery of this wheel or use by themselves for very mild abrasive action and/or wet tests. [Note, this is the same as NEMA S-32.] |

|

S-35 - #125345

Tungsten Carbide wheel set - tungsten carbide; with 1 mm pitch x 45° spiral pitch angle, helical teeth cut into its periphery ; includes left and right wheels (1 pr.). Produces very severe cutting and tearing action, use only on resilient materials. [Note: image shows protective covering on helical teeth] |

|

S-39 - #125529

Leather clad wheel set - leather strip mounted to brass hub; includes left and right wheels (1 pr.). Use in conjunction with Grit Feeder. |

|

S-42 (100 pcs.) - #125564 S-42 (500 pcs.) - #132403

The S-42 sandpaper strip includes a pressure sensitive adhesive so that it can be applied to the outer periphery of CS-0 wheels. Each strip is 12.7mm x 160mm, 180 ANSI-CAMI, open coat (100 pcs. / 500 pcs.). |

|

S-33 (100 pcs.) - #121124 S-33 (500 pcs.) - #132495

The S-33 sandpaper strip includes a pressure sensitive adhesive so that it can be applied to the outer periphery of CS-0 wheels. Each strip is 12.7mm x 160mm, 360 FEPA, closed coat (100 pcs. / 500 pcs.). |

|

Shopping Cart:

...is empty

Shopping Cart:

...is empty

Service

Service  FAQ

FAQ  My Account

My Account  My Order

My Order  Shopping Cart

Shopping Cart