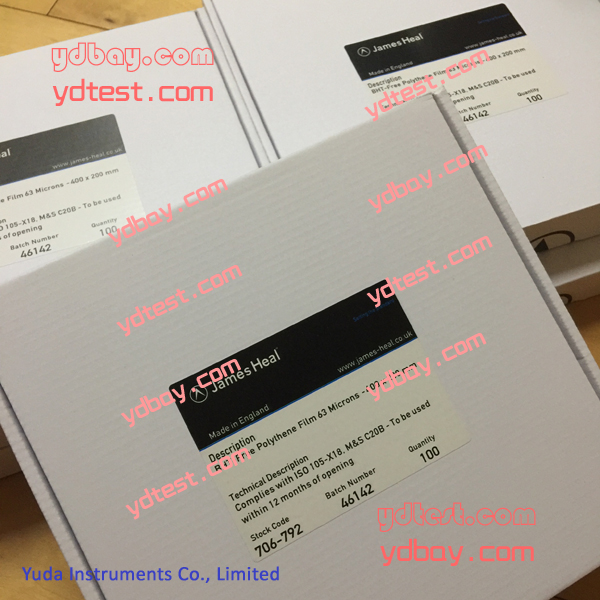

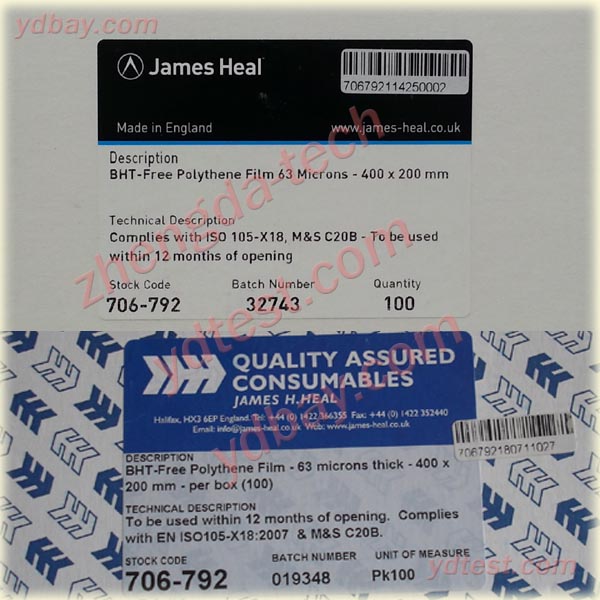

706-792 BHT-Free Polythene Film - 63 microns thick

QUALITY ASSURED CONSUMABLES James H.HEAL

DESORIPTON: - 400X200mm

TECHNICAL DESCRIPTION:Per Box(100)

To be used within 12 months of opening.

Complies with EN ISO105-X18:2007 & M&S C20B

STOCK CODE:706-709

BATCH NUMBER:013441

UNIT OF MEASURE:PK100

<

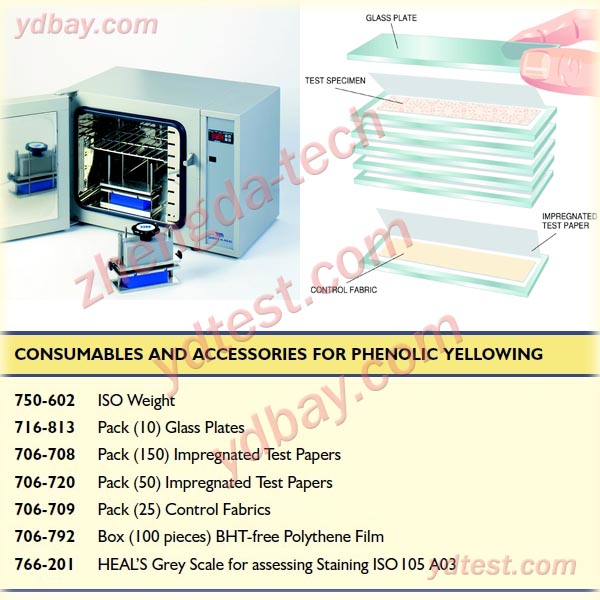

Phenolic Yellowing

This is a simple, predictive test, typically used to assess the potential of white or pastel-coloured textiles to transit or storage yellowing. The test is specific to phenolic yellowing, that is the discolouration of textiles caused by the action of oxides of nitrogen on yellowable phenols. It is not intended to deal with the many other causes of discolouration, e.g. the migration or fading of optical brightening agents, gas fume fading, the oxidation of fabric lubricants and so on.

Based on a technique originally developed by Courtaulds Research, the HEALS Phenolic Yellowing Test Kit has proved to be an effective means of controlling the quality of white and pastel-coloured goods and has considerably reduced the incidence of yellowing complaints arising from storage yellowing.

Launched in 1995, the HEALS Phenolic Yellowing Test Kit has since become established as the benchmark industry standard and is widely specified by a number of major retailers.

The risk of phenolic yellowing is evaluated by a contact test. Each test specimen is folded between a phenol-impregnated test paper. The test package consists of 5 test specimens and one standard control fabric wrapped and sealed in BHT – free polythene film. Constant pressure on the package is maintained by the Perspirometer, and the specified environmental conditions are provided by the Incubator.

On removal from the Incubator the specimens are compared with their originals and the intensity of yellowing assessed using the standard Grey Scale for Staining.

CONSUMABLES AND ACCESSORIES FOR PHENOLIC YELLOWING

750-602 ISO Weight

716-813 Pack (10) Glass Plates

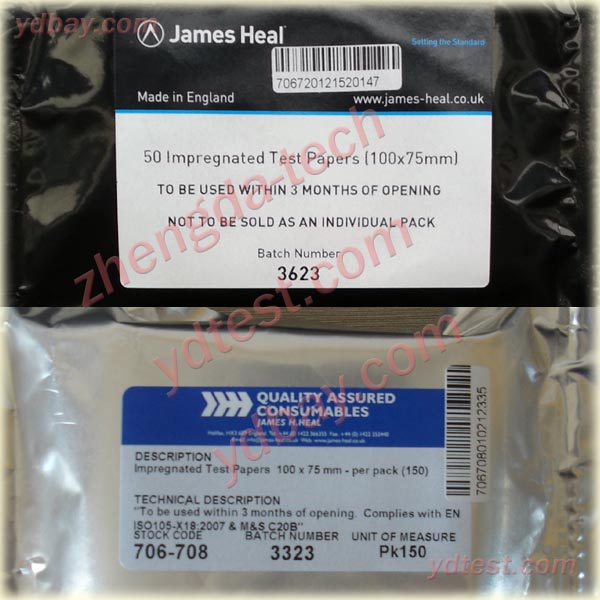

706-720 Pack (50) Impregnated Test Papers

706-708 Pack (150) Impregnated Test Papers

706-709 Pack (25) Control Fabrics

706-792 Box (100 pieces) BHT-free Polythene Film

766-201 HEAL'S Grey Scale for assessing Staining ISO 105 A03

Courtauld Test Test Methods

Purpose

• To determine the discolouration of yarns or fabrics caused by the action of oxides of nitrogen on yellow able phenols.

Apparatus

• Courtauld test equipment kit including

• Glass plates size 115mm x 60mm

• Test paper size 100 mm x 75mm

NOTE…. Once the delivered test paper package is opened the supplier guarantees accurate results for three (3) month

• Control fabric size 100mm x 30 mm

• Perspiration Stand as used for testing migration fastness

• 4.5kg weight

• Oven, compliant with DIN 50011 standards (50°C ±2°C).

Number Of Test Pieces

• 2 Test specimens, size 50mm x 75mm.

Test Procedure

1. Fold the test paper in half along its width axis so that the end measurement of the paper is 50 x 75 mm, the size of the specimen.

2. Insert the material sample between the layers of the paper. For synthetic material Place the sandwich (= material + test paper) between two glass plates (5 sandwiches plus control fabric is the highest amount which can be done in one test).

3. Wrap the package (= amount of sandwiches) firmly in 3 layers of BHT (=2,6Di-tert-buthyl-4-nitrophenol) free polyethylene film and seal it with an adhesive tape.

4. Place the package into the perspiration stand.

5. Place a load of 45 Newton's (~ 4.5kg) on top of the perspiration stand. Close the screws on the side so that the weight on the material is fixed. After fixing, remove the additional weight

6. Place the stand in an oven at 50±2 °C for 16 hours.

7. Remove the stand from the oven after the requested time and let it cool down to room temperature.

NOTE … The BHT free PE film shall only be used once, that means every new test must use a new film.

Evaluation

• Check visually if the control fabric is yellow, if so the test is successful.

• Check the intensity of the yellowing by using the grey scale for staining.

• For synthetic material both check if the backer or the surface became yellow on materials with knitwear and woven backer.

• For Synthetic material with non woven backeronly the surface is evaluated.

Shopping Cart:

...is empty

Shopping Cart:

...is empty

Service

Service  FAQ

FAQ  My Account

My Account  My Order

My Order  Shopping Cart

Shopping Cart